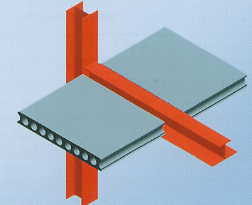

Innovative floor system consisting of special beams and prefabricated concrete plates enables to save money and building time:

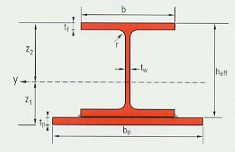

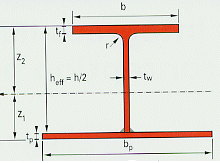

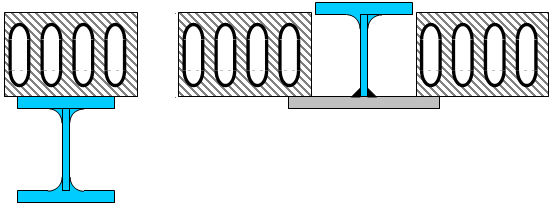

Integrated floor beams are special type of steel profiles designed for such floor system. Section shape is design to support prefabricated plate by its lower flange. Section of such beam can be combined from different rolled profiles and steel plates by welding. Two most popular shapes are shown below.

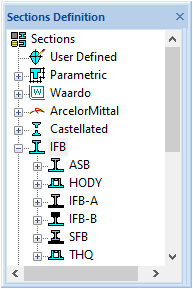

In the program this kind of sections can be applied on structure from the section tree branch IFB:

Main acting internal forces in such members is bending moment and shear forces. Additional to cross checks of ordinary simple beam lower flange of beams must be checked for bending by plate reaction. Lateral buckling resistance of such beams is guaranteed by wide lower flange.

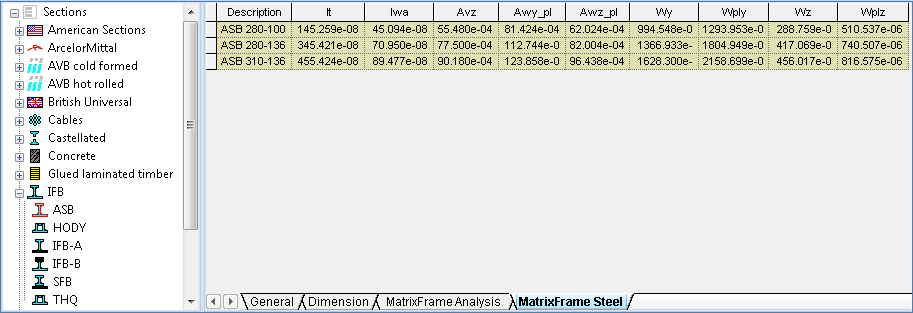

The program can calculate such shape sections only if necessary section data is provided. In general, only section included in section tree fits this requirement. It will be not possible to calculate I-shape beam with different flanges created by parametric input. It is possible to create user defined Integrated floor beam by the mean of Product Table software. For correct steel check all properties like for standard IFB-section must be provided especially in the tab MatrixFrame® Steel:

Normally a beam supporting a floor is mounted under the floor structure. This causes loss of effective height. An Integrated Floor Beam (IFB) is on equal level with the floor it supports:

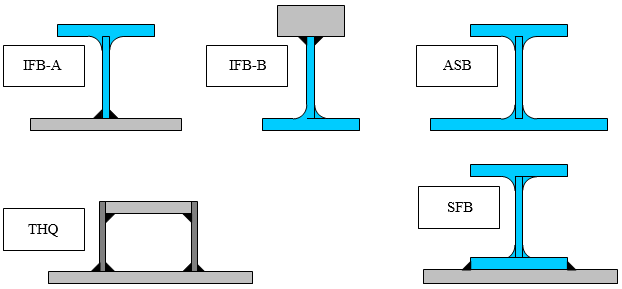

In the MatrixFrame® software there are 5 types of Integrated Floor Beam supported, as:

- IFB type A: Integrated Floor beam with original beam Above. Usually the beam is made of an I-shaped section cut in half with a plate welded to it.

- IFB type B: Integrated Floor beam with original beam Below.

- THQ: TopHatQuer beam. Looks like a hat in cross section.

- SFB: is a Solid Floor Beam, just an I-shaped section with a plate welded to it.

The advantage of such a beam is clear - saving on construction height about 25 to 30 cm per floor.

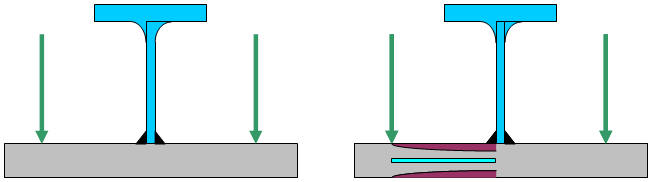

Structural disadvantage: a part of the capacity of the beam is lost to the fact that the bending on the lower flange has to be transferred inside:

The blue part of the above cross section picture is used for subtraction of shear and the purple part is for subtraction of the bending, required to get the force to the web.

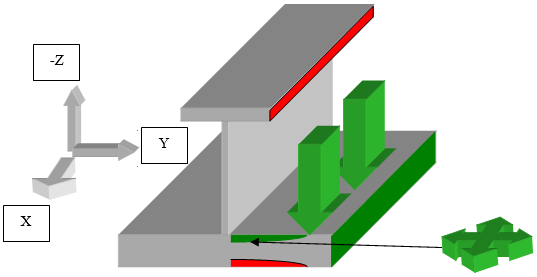

Investigating the 3D case, the red zones indicate compression, while the green zones indicate tension in the beam flanges:

- The under flange bending about the X-axis causes tensile stress on the upper side of the under flange and compression on the underside of the under flange.

- The bending of a beam about the Y-axis causes compression in upper flange and tension in lower flange. This means that on the upper side of the lower flange the stress pattern behaves as double tension in two directions like it represents the arrow graph next to it. In that area the stresses in two directions with the same sign are represented. In such case is not needed to reduce the capacity for that area. Because the "work" in one directions does not affect the capacity in the other.

In the general case, by acting different forces in the cross section, the reduction of the cross section for the influence of particular force influence has to be investigated: