|

Parameter |

Description |

|

Stiffener |

Column-End plate joint connection stiffeners |

|

Height |

Height of a stiffener |

|

Width |

Width of a stiffener |

|

Thickness |

Thickness of a stiffener |

|

Distance |

The distance between the upper edge of the stiffener to the folded upper edge of the side plate; taking into account, it can be continued upwards with a negative sign |

|

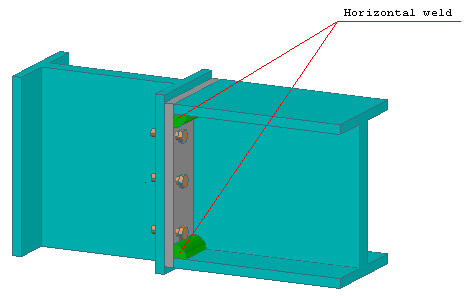

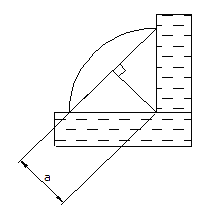

Horizontal weld |

The throat thickness of the horizontal weld at the intersection of two connected members:

|

|

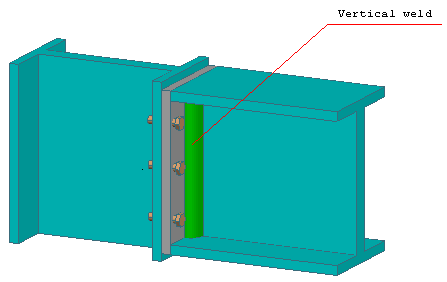

Vertical weld |

The throat thickness of the vertical weld at the intersection of two connected members:

|

Weld steel material name is used for code check calculation and supported by EN 1993-1-1#Table 3.1 and related national annexes such as NEN-EN 1993-1-1#3.1. Weld steel list depend on chosen code or/and national annex.

Check welding in connection

Such types of checks are performed for welding:

- Capacity of fillet welds connecting endplate and beam cross section for bending and shear;

- Capacity of fillet welds connecting diagonal and horizontal stiffeners to column flanges for axial tension or compression forces;

- Capacity of fillet welds connecting flange of haunch to beam flange and endplate of beam;

- Welds connecting webs and stiffeners can be provided as nominal and will not be checked.

Capacity of welds must be not less than bearing capacity of stiffeners and haunch.

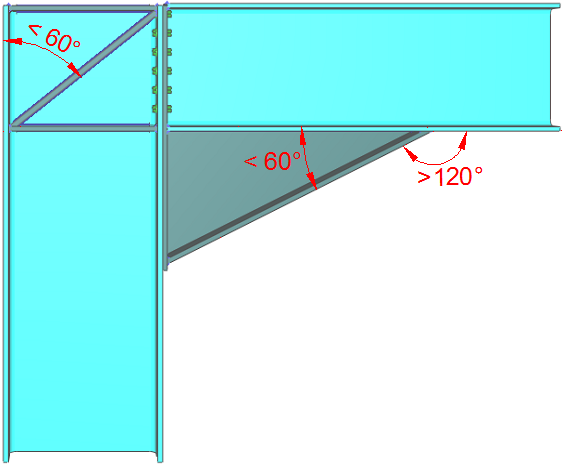

If during design of connection angle between fusion faces becomes less than 60° or more than 120° warning in reports and tooltips: "Full penetrated strength butt welding must be applied as welded elements angle < 60° or >120°" (see EN1993-1-8 #4.3.2.1) will appear:

Proposal is used for determining the optimal logical values of parameters and measurements of the structure elements as well as the optimal arrangement of these elements from geometrical point of view (not based on UC's). Proposal offers the optimal allowed modification of the construction model by making any necessary changes to the data entered by the user.