1. Fabrication phase (Remove/release prefab formwork phase) of the structure

Fabrication phase (Remove/release prefab formwork phase) is dedicated exclusively for the calculation of the pre-stressed element, where only the dead load and the pre-stressing actions of the pre-stressed element or its part is taken in to account.

Structural model which contains more than one pre-stressed element is interpreted as trimmed (disjoined) structure, where each trimmed part is investigated as separate element, have no common relations:

Pre-stress actions (initial and acting) is generated/represented/placed on each trimmed (disjoined) pre-stressed element of the structural model separately.

Pre-stressed element is represented by the single cross-section. Pre-stressed element has more than one cross-section is not valid.

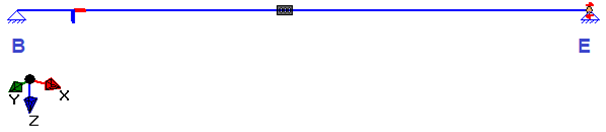

Fabrication phase (Remove/release prefab formwork phase) structural model has a set of predefined supports and releases, and can’t be changed by user input:

Supports: On the begin(“B”) and the end (“E”) of the structural element “Pinned” (Yr=Free, free rotation around Y axis) support is used.

Release: On the end (“E”) of the structural element as X = Free (free movement of the node in X direction).

2. Montage phase of the structure

During the "Montage" phase the pre-stressed and/or pre-fabricated (Prefab, without pre-stress features) only elements (cross-sections) are investigated. All other elements (sections) not marked pre-stressed and/or pre-fabricated are ignored;

Montage phase investigation assumes:

- Possible definition of restrains (supports and/or releases) specific for the montage phase only;

- Transient loads generation/definition;

- Transient loads combinations generation/definition;

- Structural analysis and code check including transient actions and the "Remove/release prefab formwork" phase gained forces/deformations.

3. Using of bi-material (pre-stressed + compressed layer) cross-section

By default, the compression layer of the cross-section used for the "Montage" phase is treated as the dead load, while the structural analysis calculation is performed using the section properties of the bottom layer of the cross-section, neglecting the compression layer.

The default situation for the "Montage" phase for the whole project can be changed using options: Customize -> Settings -> User list -> Phases.

The structural analysis and code check performed for the Remove/release prefab formwork phase is only subject to the prefabricated/pre-stressed part of the cross-section, while the compression layer is constantly accounted for in the "End of life" phase.

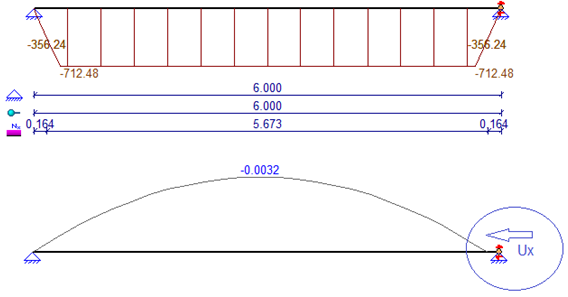

4. “Shortening” of the pre-stressed element during production phase

During the fabrication (Remove/release prefab formwork phase) pre-stressed element is influenced by the initial or acting axial forces. Axial actions invoke axial deformations, which is seen on the deflection line of the element:

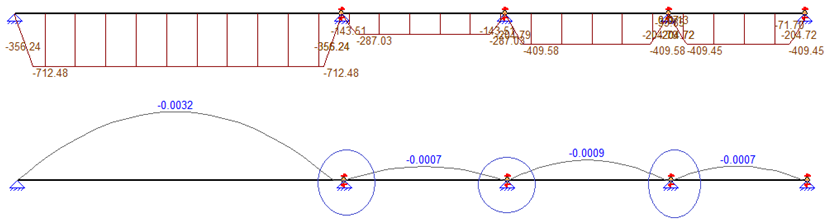

The fabrication phase structural forces/deformations is kept also by using multi elemental structure. It causes appearance of discontinuous deflection line:

5. Calculation of the complex topology strip structure

Calculation using different cross-sections and/or pre-stress features over the length of the beam is optimized for the performance (internal splitting). This can cause inaccuracy in calculation (less than 0.1%) by compare to the separate calculated part of the structure (without optimization, internal integration).